Lean and Six Sigma success

Lean Success

Lies in

Improving efficiency by removing wastes

Six Sigma Success

Lies in

Improving process capability to reduce variation

A LEAN SIX SIGMA PROGRAM is an improvement approach aimed at combining both Lean and Six Sigma to:

Improve efficiency and capability by removing wastes and reducing variation

Lean and Six Sigma Approaches

Program | Lean Thinking | Six Sigma |

|---|---|---|

Theory | Remove Waste | Reduce Variation |

Application guidelines | 1. Identify value

2. Identify Value Stream

3. Flow

4. Pull

5. Perfection | 1. Define

2. Measure

3. Analyze

4. Improve

5. Control |

Focus | Flow and waste | Problem and detection |

Format | Kaizen event on a short timeframe for quick & initial gain | Project-based spread over months of in-depth study |

Level of competency | For everyone | High (need some science) |

5 Questions Determine the Success!

- 5S Workplace

- Cellular Production

- Value Stream Mapping

- Pull Production

- Poka-Yoke

- Quick Changeover

- Demand/Load Leveling

- Visual Management

- Employee Involvement

- Total Productive Maintenance

- Process Mapping

- SIPOC

- SPC

- FMEA

- DOE

- QFD

- MSA Gauge R&R

- ANOVA

- Multi-Vari

- Hypothesis Testing

- Regression

- Which one to use?

- How to use?

- How often?

- Partial or full impact?

- Who is leading?

Lean and Six Sigma Comparison

Lean | Six Sigma | |

|---|---|---|

Theme of reduction | Waste | Variation |

Key justification | Speed | 3.4 DPMO |

Saving from | Op. Cost | COPQ |

Learning Curve | Short | Long |

Technicality | Moderate | High |

Project Leadership | Kaizen | Black Belt |

Integrating Lean & Six Sigma

Results are superior to what either system could achieve alone.

By looking at projects through both the lean and Six Sigma lenses, you have the precision, actionable tools needed to find hidden problems while making sure you don’t overlook the obvious.

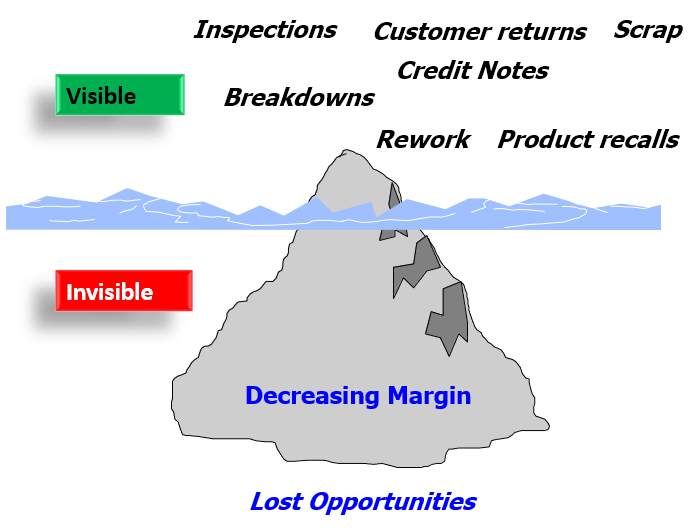

Non-Quality Costs

Too many product redesigns

Extra Delivery Cost

Loss of credibility

Insurance cost

Lost sales, poor margins

Demotivated people

Slow time to market

Late delivery

Excessive Cycle Time

Excessive inventory