Certification:

Participants shall be certified as Lean Six Sigma Black Belts upon the following criteria:

- Class attendance and active participation

- Passing the Mini Exams at the beginning of each Black Belt Block with an average of 70%.

- Passing an exam at the end of the course with 70% or more.

- Implementation of a Lean Six Sigma Black Belt project which is applied in the participant's business process which will be verified through Symbios Consulting representative onsite Visit.

- Participants who attend all classes and pass the exam with more than 70% shall be granted only an Accomplishment certificate for the course.

- Participants who attend all classes shall be granted only an Attendance certificate for the course.

- Participant should finish the project within a maximum of one year after the training. In case he didn't, he will be granted an accomplishment certificate.

Who should participate?

- Quality Managers

- Production Managers

- Supply Chain Managers

- Production supervisors

- Process Improvement Teams

- Business Transformation Teams

- Improvement Leaders

Course Duration:

Lean Six Sigma Black Belt Certification program is designed to be delivered as follows:

- 13 full class days, 104 hours in 6 blocks

- Training starts 9:00 am till 5:00 pm

- There will be Individual projects reviews and presentations at Symbios premises

- Two visits for each participant in his/her work area to verify project progress for certification:

- First visit 2 weeks after the second block

- Second visit 3 weeks after the fourth block

- 1 day for the Black Belt final exam.

Admissions Pre-Requisites:

- Each participant brings a laptop with any version of Minitab software installed.

- Knowledge of Ms-Excel

- Very good command of English

- Company approval for project implementation

Our training programs are accredited from OPEX Canada and from Council for Six Sigma Certification in the USA

www.opex-academy-for-certification.ca

www.sixsig macouncil.org

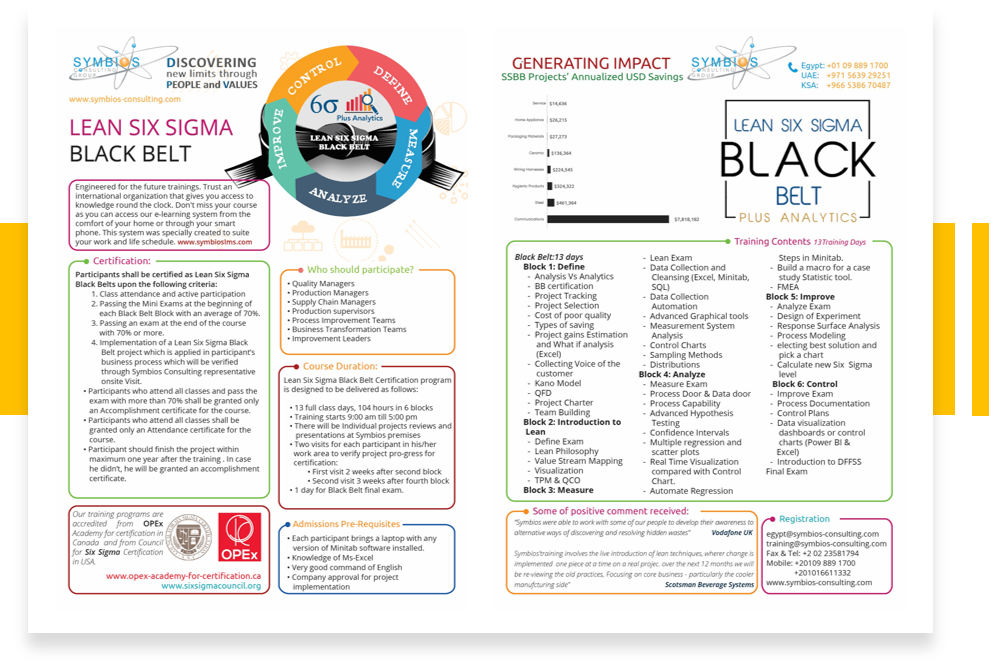

Training Content:

Black Belt:13 days

Block 1: Define

- Analysis Vs Analytics

- BB certification

- Project Tracking

- Project Selection

- Cost of poor quality

- Types of saving

- Project gains Estimation and What-if analysis (Excel)

- Collecting Voice of the customer

- Kano Model

- QFD

- Project Charter

- Team Building

Block 2: Introduction to Lean

- Define Exam

- Lean Philosophy

- Value Stream Mapping

- Visualization

- TPM & QCO

Block 3: Measure

- Lean Exam

- Data Collection and Cleansing (Excel, Minitab, SQL), Data Collection Automation, Advanced Graphical tools Measurement System Analysis

- Data Collection and Steps in Minitab.

- Control Charts

- Sampling Methods Distributions

Block 4: Analyze

- Measure Exam

- Process Door & Data door

- Process Capability

- Advanced Hypothesis Testing

- Confidence Intervals Multiple regression and scatter plots, Real-Time Visualization compared with Control Chart.

- Automate Regression steps in Minitab.

- Build a macro for a case study Statistic tool. FMEA

Block 5: Improve

- Analyze Exam

- Design of Experiment Response Surface Analysis

- Process Modeling

- Electing best solution and pick a chart

- Calculate the new Six Sigma level

Block 6: Control

- Improve Exam

- Process Documentation Control Plans

- Data visualization dashboards or control charts (Power Bl & Excel)

- Introduction to DFFSS

Final Exam

Registration:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Fax & Tel: +2 02 23581794

Mobile: +20109 889 1700

+201016611332

www.symbios-consulting.com