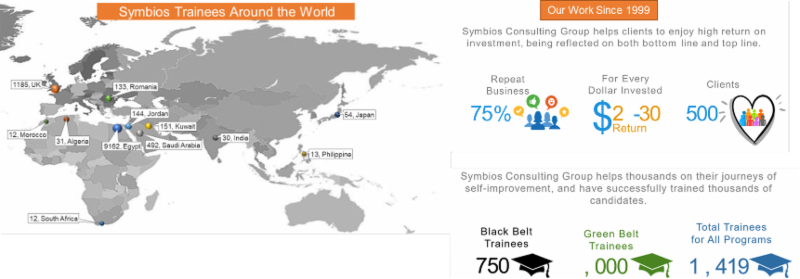

It was somewhere in 2012, the local Saudi business group Alliance Holding which runs General Lighting Company went for business partnership with American multinational Carlyle group. We can say this is the start point of thinking about “Lean” for the success in the organisation. Some lean experts from Carlyle group made few visits to think about lean manufacturing with the top management of JV of General Lighting Company and Carlyle. In this period, the management started to look to hire a consultant to implement the lean tools. Various lean consultants were considered but finally decided to go with Symbios because of two reasons:

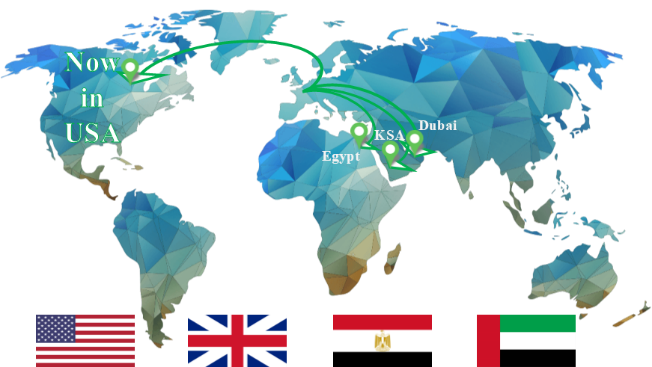

1) Their presence in the Middle East region from long time and know the culture of the local as well as expat people working in this region.

2) Their customer base mostly with manufacturing industries

Philips is one of the companies known for their endeavors to shape the future by being inovative and constant improvement of its business environement, tools and products.

The journey started in 2013, mainly focusing on Loss Analysis and implementing 5 S. Training was conducted throughout the last three years on Lean Green Belt, Statistical Process Control & Lean Supervision.

Challenges that the General Lighting Company and now Philips Lighting has faced and the main areas for improvements:

The company is in lighting business for more than 35 years and the main focus for the company is to fulfill the customer orders as much as possible, while providing a wide variety of choices as its main strength but all this was done by maintaining huge raw materials, finished goods inventory and producing the goods in batches.

Little focus was given to how it was produced, distance and time taken in the process and how many days it lies in the shop floor as “work in process” and as finished goods in the warehouse. The company hired 6 rented warehouses in different locations around the factory to fulfill the demand!

So the areas for the improvement was clear – reduce the production time, inventory and increase the customer satisfaction level!

Lean was obvious the way to identify saving opportunities in time, inventory and resources.

Lean increases capability of workers through extensive training that targets key personnel, supervisors and cascaded down to all workers.

Areas of achievements and satisfaction level of meeting the objectives set:

In the last 4 years of lean journey there is a big improvement in many areas;

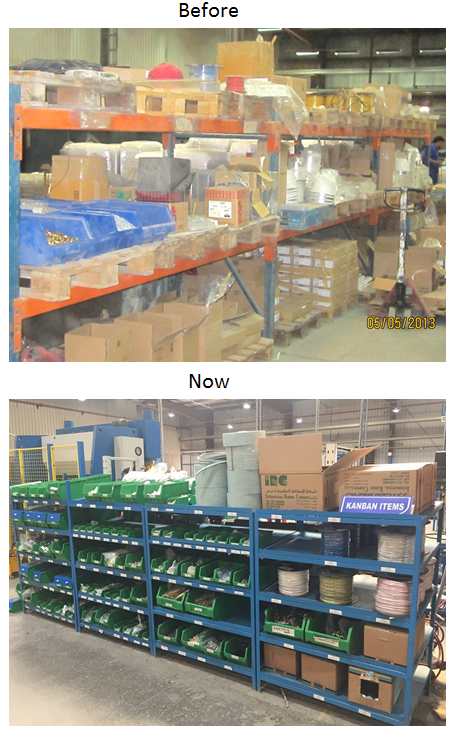

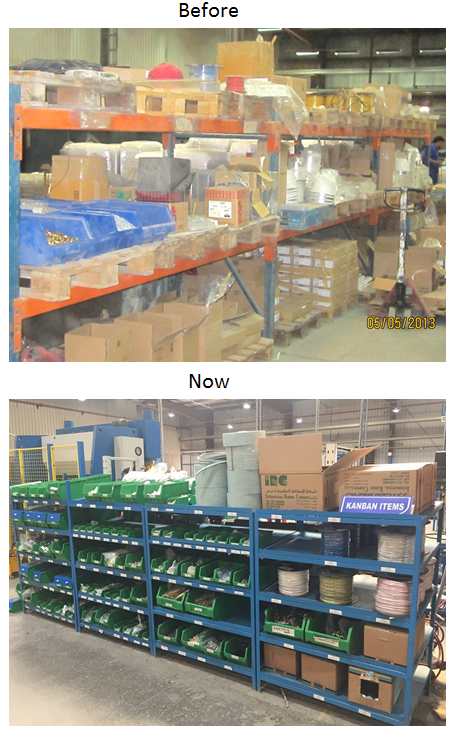

Lean culture has started with trainings on usage many tools; 5S is the one of the important tool which helped us to gain more floor space through Red Tag activity.

Implemented Kanban in the shop floor and at finished goods. The shop floor planning in some areas is through Heijunka board which is helping the supervisors what exactly to produce! All these tools helped us to reduce the inventory.

Changing from batch production to one piece flow by forming the small manufacturing cell helped into building the team culture, line balancing and equal work distribution, SMED tool reduced the set up time. Over all we gained more than 25% of floor space in all three factories!

Through Kaizen events, people participation in giving the Kaizens increased, through Gemba walk in factory and warehouse with line managers and engineers increased more awareness for the employees on Safety, quality and process improvements. TPM system brought many unresolved maintenance issues into closed, started to use daily performance meeting and started measuring the performance through KPI. Started to use the tools like A3, 5Why for major issues.

After JV was made with Philips Lighting in 2014, the company started to recognize the real benefit of implementing the lean as this culture is already in place for many years with Philips lighting. Since the JV has to move with the same phase of lean with other Philips companies worldwide, there are few big tasks; challenges are to be fulfilled by joining hands with Symbios Consulting.

Areas where Symbios exceeded expectation:

In building the new layout and re-layout, lean concepts were widely and wisely used. Through green belt training program, many engineers/supervisors are involved in improvements through Lean projects. Taught us on how to use Hoshin planning system so that the management team and their team members started thinking for 1 to 3 years goals and objectives.

Few examples showing how Philips has moved forward:-

Trainees setting their departmental objectives, setting their KPIS and personal duties and responsibilities increases their commitment to making it a success.

Copyright © 2017 Symbios Consulting, All rights reserved