Abdel-Hamid Ahmed | Operational Excellence Consultant

Abdel-Hamid Ahmed | Operational Excellence Consultant ![]() This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Shereen Mosallam | Operational Excellence Consultant

Shereen Mosallam | Operational Excellence Consultant ![]() This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

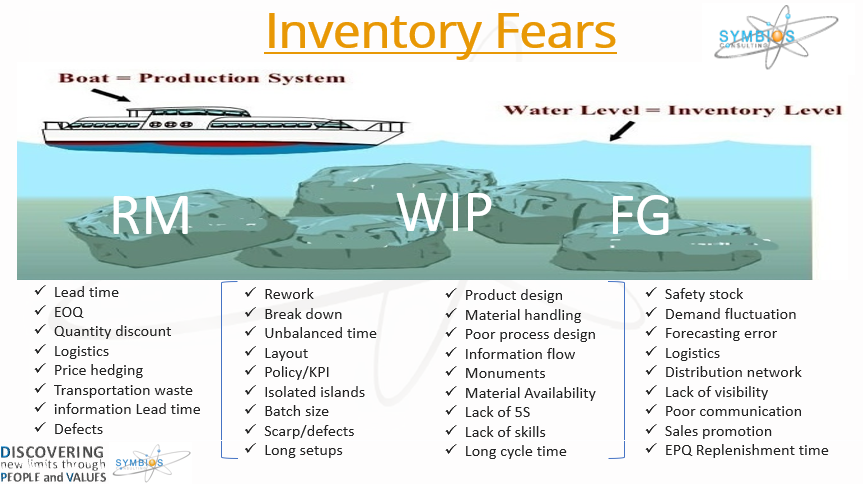

The stock has more many types (raw materials, work in process, spare parts, or finish products)....

- Lead time - Rework - Product Design - Safety Stock

- EOQ - Breakdown - Material Handling - Demand Fluctuation

- Quantity Discount - Unbalanced Time - Poor Process Design - Forecasting Error

- Logistics - Layout - Information Flow - Logistics

- Price Hedging - Policy/ KPI - Monuments - Distribution Network

- Transportation Waste - Isolated Islands - Material Availability - Lack of Visibility

- Information Lead Time - Batch Size - Lack of 5S - Poor Communication

- Defects - Scrap/ Defects - Lack of Skills - Sales Promotion

- Long Setups - Long Cycle Time - EPQ Replenishment Time

We maintain inventory for many reasons, including "external and internal" reasons, which are summarized according to APICS in the following:

- Safety stock

- Buffer

- Anticipation inventory

- Lot size inventory

- Transportation inventory

- Hedge inventory

The Japanese call the stock a wall of shame, while many companies and the traditional accounting system consider it as the company's asset.

It is acceptable for us to build a large stock for “External” reasons, but unfortunately, in reality, a lot of companies are maintaining for "internal" reasons as well.

Whether the driving reasons for keeping the stock, internal or external, can be dealt with and work to solve it, such as cooperating with suppliers or studying the reasons for changing the market demand.

Unfortunately, we coexistence with the problems and the causes of these fears and we get used to it as if it was beyond our control without challenging ourselves.

When calculating the Process Cycle Efficiency (PCE) in the Lean projects, we calculate the “value add” percentage for the lead time, which is less than 1%, and most of the time consumed is the result of keeping a large stock.

You should focus on how to improve the supply chain and be “lean” in your company because inventory is one of the 7 deadly wastes in any process.

All this is because we give in to our "Inventory Fears".

We wanted to share with you some of these concerns or problems in detail, and we categorized them according to each type of inventory. Some companies have a problem with one or two types but unfortunately, some of them have a problem in all three types, all three of these problems affect your business and cash liquidity.

This does not mean that we live with zero stock, but we must control it and work on reducing it.

Sometimes some industries need to keep a stock of the finished goods or raw materials depending on the nature of the industry, such as the manufacture of home appliances. It is better to keep a stock of FG to save storage space of many components, but this does not mean that we maintain a stock of RM, WIP, and FG.

The quantity of the safety stock must also be calculated because many companies simply because of the lead time of the supplier 3-month they keep stock for the same period without using the formulas designed to calculate the safety stock "we will talk about it later at another time".

We must also use a frequent replenishment to replace what has been consumed to reduce inventory, instead of requesting more than we need to save the cost of the request.

We imagine this inventory is an “asset”, although it is a “liability”.