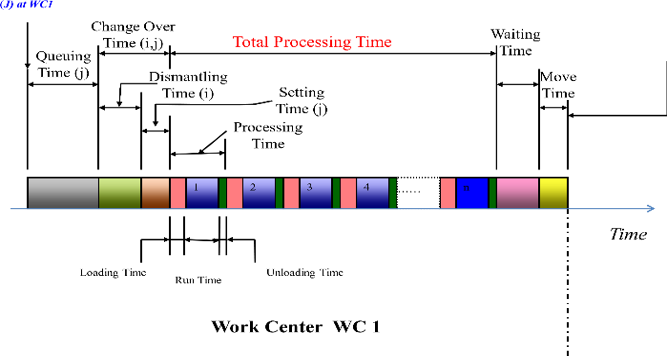

Lean Experts and Manufacturing Gurus are constantly working on reducing * LEAD Time (Lead time is the amount of time that elapses between when a process starts and its completion. Lead time is examined closely in manufacturing, supply chain management and project management, as companies want to reduce the amount of time it takes to deliver products to the market.

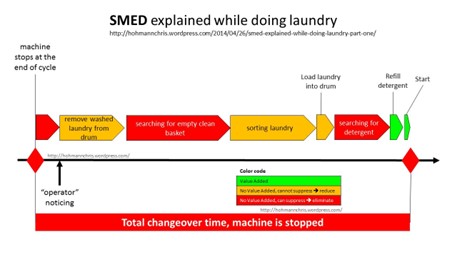

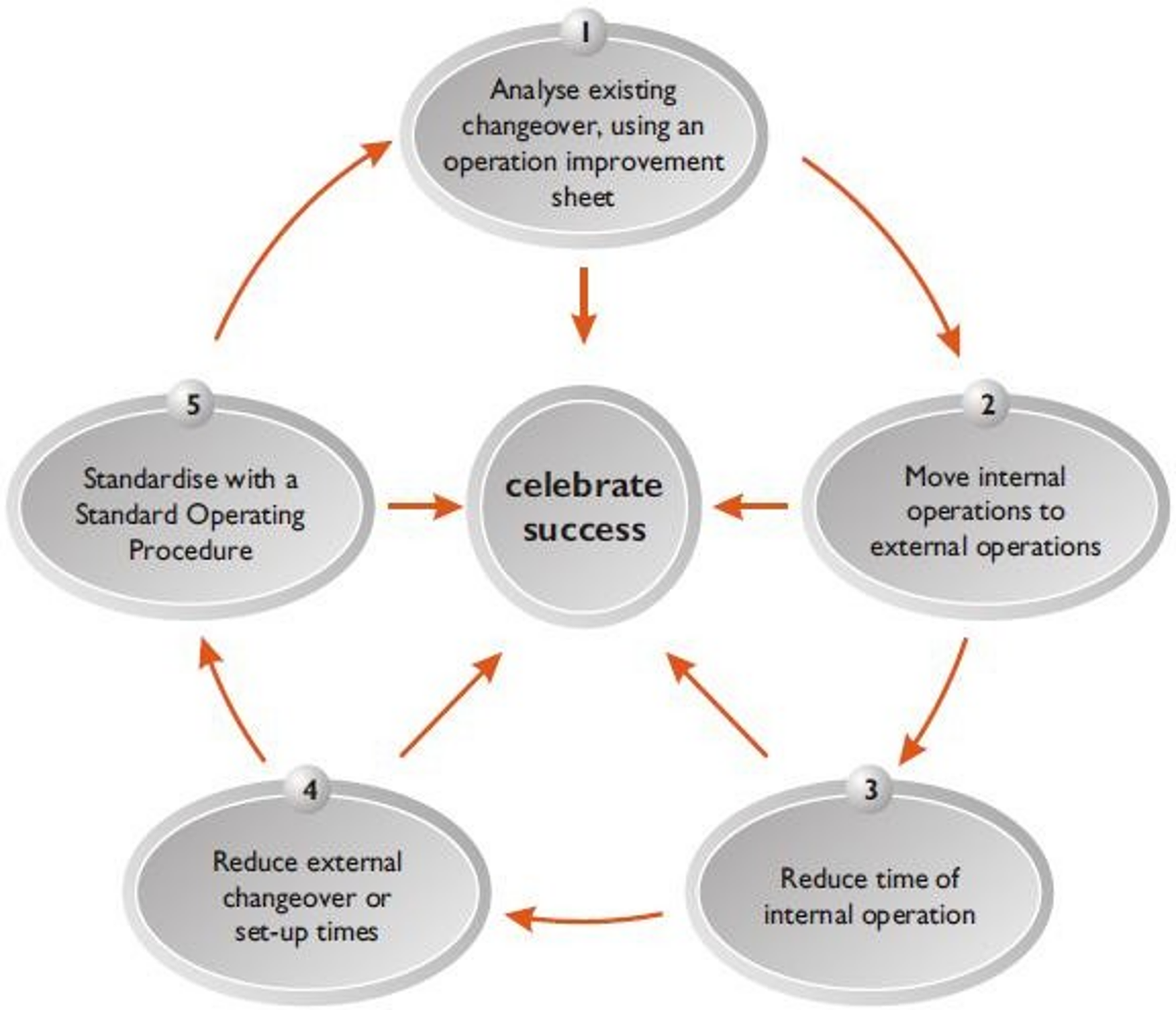

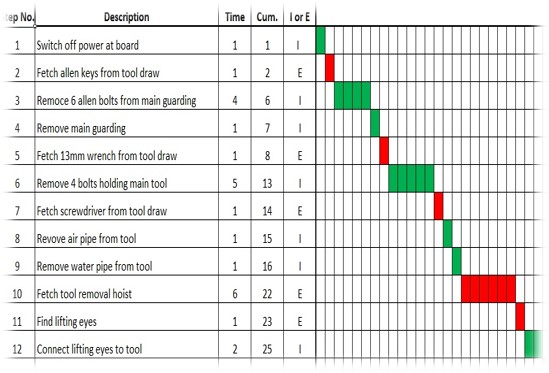

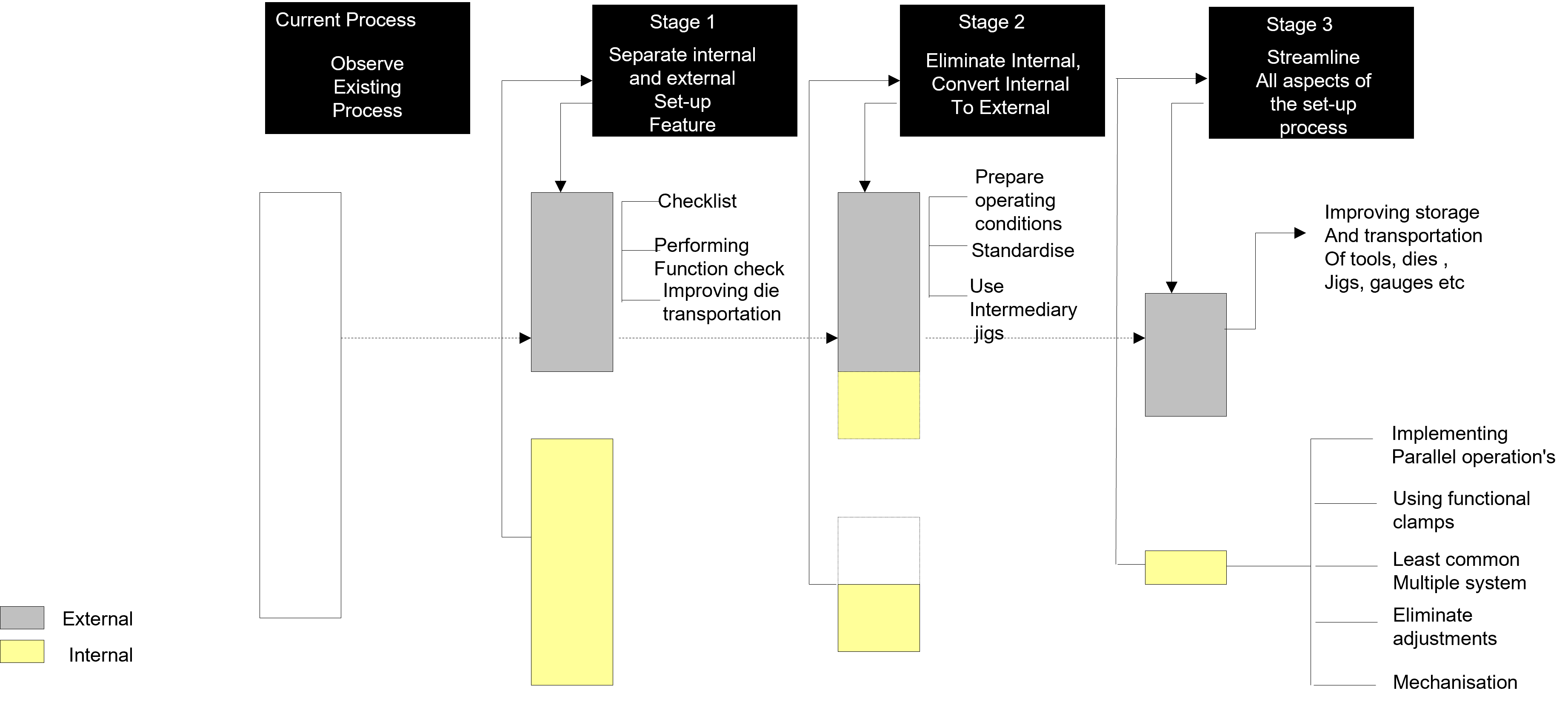

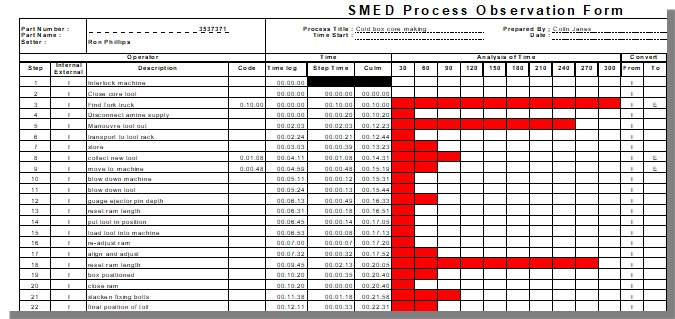

When The Japanese Engineer Shigeo Shingo developed the concept of * SMED (Single-Minute Exchange of Dies) is a system for dramatically reducing the time it takes to complete equipment changeovers., he managed to reduce the changeover time from an average of 40-20 to only 5-1 minute.

The concept relies on carrying out some changes while the machine is stopped and continue the rest while it is running.

Nowadays, manufacturing engineers are working on replacing the changeover cycle in only 1 minute naming it SCED (Single Cycle Exchange of Dies)

It is applied in offices too. We want SCED in information retrieval, DR IWAO Kobayashi has come out with SMIR more than 25 years ago. Key 5 and key 1 in admin,

Watch the video below- Formula One pit lane is an example of SMED in its purest form:

SMED is not only for dies

It is for shift startup

Handover between two shifts

Between two operators

Loading finishing and starting a new truck

Lot to lot or batch to batch

Color/ flavor changeover

Packaging machines

Startup after maintenance

Offices:

Morning startup at work.

Handover of tasks

Switching from a task to another

Supervisor handover

Information retrieval

Meeting rooms clearing to start another meeting

Time between finishing a Customer and starting following customer

Hospitals:

Patient to patient at clinic

Surgery room changeover

Patient to patient at dentist

It is everywhere

Watch the video below- Quick mold change in less than 3 minutes

When we talk SMED and QCO, many people would think it is a manufacturing tool only. Yet it is not.

Key Objectives

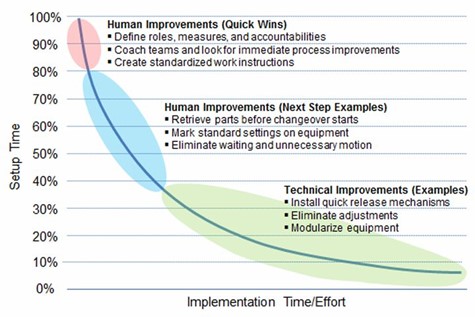

- The key to organizational competitiveness is flexibility and quick customer responsiveness.

- Quick Changeover aims to improve the flexibility and responsiveness of the company and also to eliminate waste by reducing all changeover times in the workplace.

- Shorter lead times are a key ingredient for adaptability and increased customer service levels. This can often only be achieved by reducing changeover times.

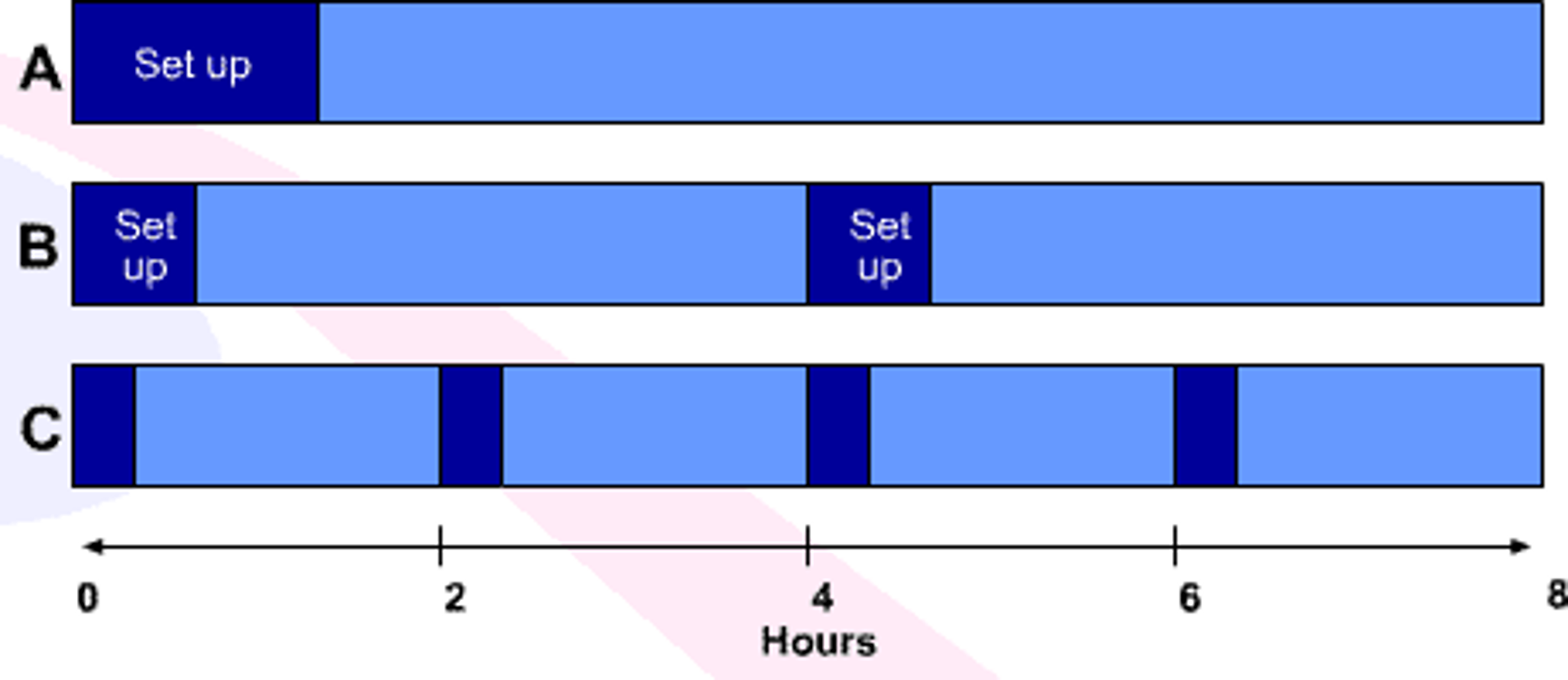

- Reducing changeover times is not only about increasing the time available for production, but also about being more flexible. With short changeover times, more changeovers can be done, resulting in flexibility, shorter lead times, faster response and lower inventory.

More Photos

Questions need answers

- Phases of SCED?

- Similar areas of SMED and SCED?

- Difference and value add in applying SCED rather than SMED?

Stay Tuned for the next article

more blogs here: https://symbios-consulting.com/blog.html